Often, people mistakenly believe that stainless steel is a single material. In reality, stainless steel refers to a family of corrosion-resistant steels. Therefore, it is very important for a consumer to understand the distinctive properties of various families and grades of stainless steel so that he can make an informed decision.

Even though stainless steel owes its corrosion resistance primarily to chromium, there are many combinations of metals available in the market today, which also fall within the category of ‘stainless steel’.

When you try to find the best option of stainless steel, you must determine the precise kind of alloy you require for your purpose. That will also help you identify the optimal price point according to your need.

The two major stainless steel labels are:

a) Families

b) Grades

Stainless Steel Families

The term ”stainless steel families” in this case refers to specific properties of that particular alloy. Different families have different ratios of various metals in the alloy. The four prominent stainless steel families include:

a) Austenitic

b) Ferritic

c) Duplex

d) Martensitic and Precipitation Hardening Stainless Steel

While families act as a differentiator at one level, you need to really look at grades of stainless steel to appreciate what separates one variety from another. Various grades refer to specific properties of the alloy such as toughness, magnetism, corrosion-resistance, and alloy composition.

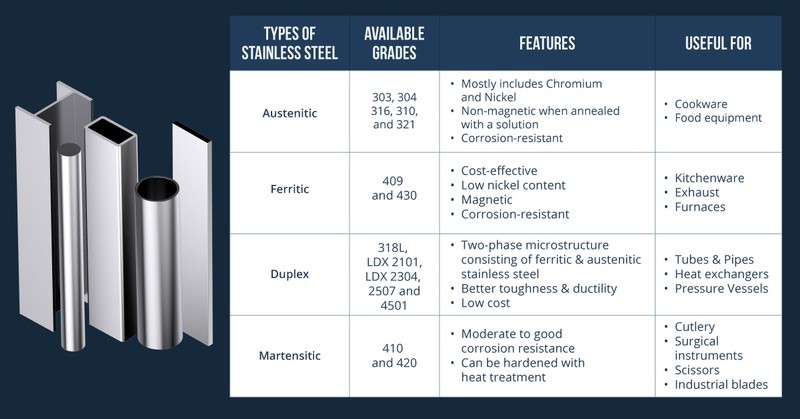

Common stainless steel families and grades along with their characteristics:

Pairing a family and grade together gives you a good indication of what to expect from a particular stainless steel alloy. Be it magnetism, toughness, corrosion-resistance or heat-resistance, you can learn about everything by focusing on these two aspects.

The following classifications will make you aware of what to expect within each family as well as common grades.

Austenitic: This is the most widely used family of stainless steel worldwide. It mostly includes chromium and nickel, though some grades also include manganese and molybdenum. Austenitic stainless steel is non-magnetic when annealed with a solution. However, there are also certain cold worked grades that are magnetic. Heat-based hardening does not work for this type of stainless steel. However, it promises excellent corrosion-resistance and is also highly weldable. Austenitic stainless steel’s popular grades include 303, 304, 316, 310, and 321 grades.

Ferritic: This is one of the most cost-effective families of stainless steel available in the market. It has a low nickel content but includes chromium, molybdenum, niobium, and/or titanium. These metals improve the toughness and creep resistance of this alloy. This variety is magnetic, highly corrosion-resistant and weldable. Its most popular indoor applications include kitchenware, exhaust etc. This family is well-suited for applications where cost and performance matter more than visual appeal. Common grades of ferritic stainless steel include 409 and 430 grades.

Duplex: This family includes most of the recent and proprietary stainless steel alloys. If you opt for duplex grades, you can benefit the most from its properties, which are a combination of both austenitic and ferritic stainless steels’ properties. When it comes to the Duplex family of stainless steel, its characteristics depend upon the specific alloy. The characteristics include weight, toughness, and tensile strength. A number of alloys are created based on specific industrial concerns. This family of stainless steel is also available in a chloride-resistant variety, which is popular in offshore use. In this family, the common grades include 318L, LDX 2101, LDX 2304, 2507, and 4501.

Martensitic and Precipitation Hardening: Martensitic and precipitation hardening steels are the most common of the four major families of stainless steel. These are popular in applications that need a precise and hardened edge. This family is also the best choice for making knives, scissors, razors, and medical tools. This stainless steel alloy promises moderate to good corrosion-resistance and retains its magnetism after hardening. 410 and 420 grades are the common grades of martensitic and precipitation hardening steels. Be it making ornamental structures or rugged industrial applications, stainless steels have a wide range of usages and applications. It is crucial to understand the unique characteristics of different stainless steel alloys so that you make the right choice.