Steel as a broad term is loosely used to refer to an entire family of metal alloys. It is a common, highly versatile metal with a wide range of applications and uses. Steel comes in different grades but generally speaking, it can be divided into two categories: a) Carbon Steel b) Stainless Steel.

The basic attribute that differentiates the two is the chromium content. While carbon steel contains less than 10.5% of chromium, stainless steel must have at least 10.5% of chromium to be classified as the same. It is this characteristic that lends different properties to the two types of steel.

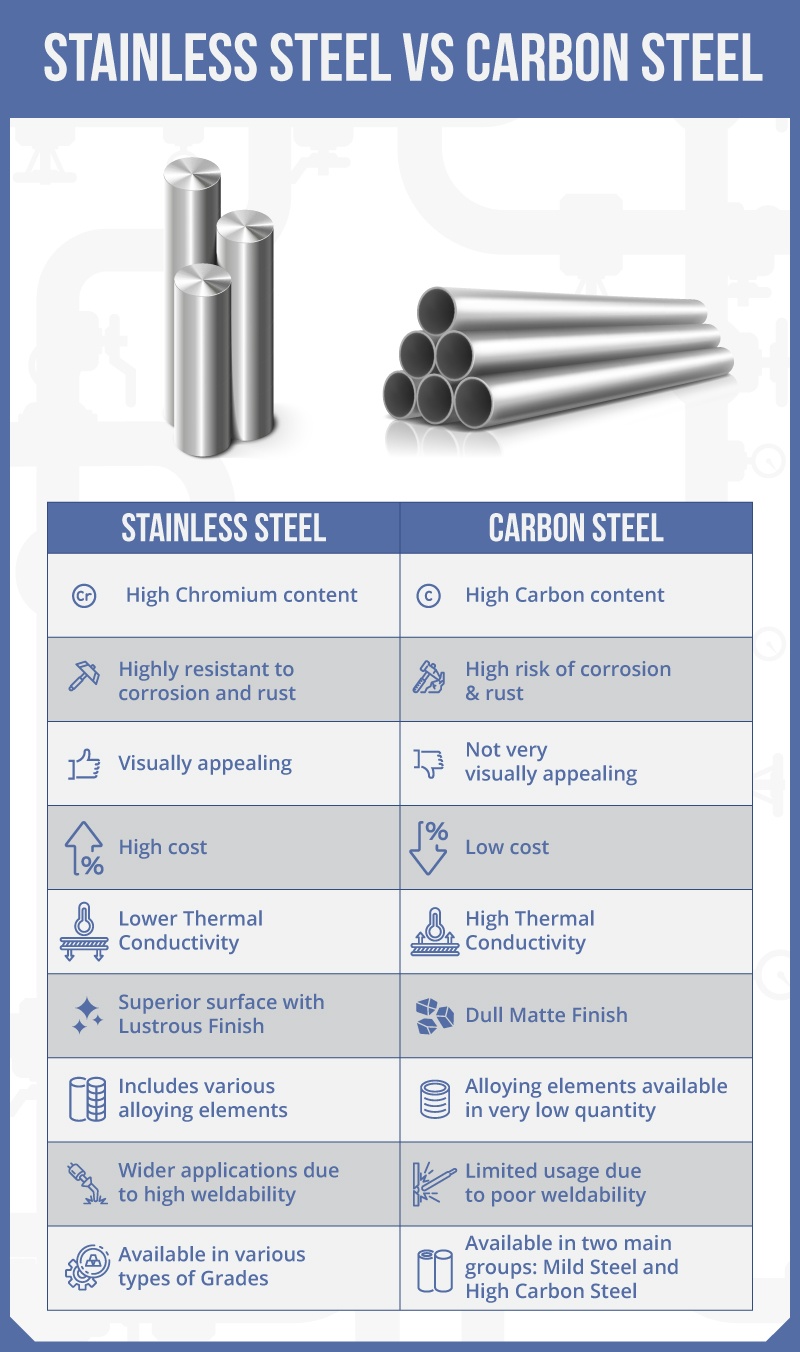

Difference between Stainless Steel and Carbon Steel:

Stainless Steel

This is mainly defined by the addition of chromium, along with certain other alloying elements such as nickel. It is also termed as ínox’ steel, as it is crafted to protect against oxidization, and hence, it is ínoxidizable’. Equipped with the protective layer of chromium which safeguards the metal’s iron content from being oxidized due to exposure to environmental oxygen, stainless steel is corrosion-resistant and thus called ‘stainless’.

Types of Stainless Steel

Depending on the chromium levels, stainless steel can further be divided into various categories. Usually, stainless steel with lower chromium content is cheaper and less durable. The following are the types of stainless steel with different properties:

Austenitic: This is the most widely used type of stainless steel, offering low yield strength but strong corrosion and heat resistance. It is commonly used in housewares, industrial piping and vessels, construction, and architectural facades.

Ferritic: This form of stainless steel usually does not contain nickel. However, this promises better corrosion, heat, and cracking resistance as compared to most other types. This form of stainless steel is frequently used in washing machines, boilers, and indoor architecture.

Martensitic: This is usually magnetic and due to its low chromium content, is not as corrosion-resistant as other types of stainless steels. It’s also very strong, and therefore, it’s used to make knives and turbine blades.

Duplex: This is a composite of austenitic and ferritic steels, and is thus, very strong and flexible. It boasts twice the yield strength of austenitic stainless steel and finds wide usage in industries such as paper, pulp, shipbuilding, and petrochemical industries.

Precipitation: This type of stainless steel has the same level of corrosion resistance as austenitic metals, but can be hardened to make it even stronger by adding other elements such as aluminum, copper, and niobium.

Advantages of Stainless Steel

– Corrosion-resistant

– High and low temperature-resistant

– Comes in different types

– Strong and highly durable

– Low-maintenance and can be easily cleaned

– Long-lasting

– Low-priced as compared to its lifespan

– Can be customized for an attractive cosmetic finish

– Does not tarnish easily

– Environment-friendly and recyclable

Applications:

Stainless Steel has a range of applications in many industries. The first industrial application of stainless steel took place way back in the 1930s by Ford, in the automotive industry. Ever since then, it has made its way into cars for exhaust systems, grills, trims, and different structural components. It is also used in aircraft construction, for making aeroplane frames, jet engines, and landing gear. Its corrosion-resistance and low-maintenance properties makes stainless steel highly useful for transporting and interacting with chemicals. Medical technology uses stainless steel too.

Thanks to its strength, resistance, and flexibility, certain types of stainless steels are used in architecture. The aesthetic features and attractive finish of stainless steel further enhance its desirability in architectural applications. It can also be cleaned easily. No wonder stainless steel’s price is considerably higher than carbon steel.

Besides, stainless steel is commonly used in the food and catering industry to manufacture cookware, cutlery, kitchen accessories, and appliances. It is interesting to note that the less ductile grades of stainless steel are used to make utensils such as knives, while the more ductile grades are used in the manufacture of grills, ovens, saucepans, and sinks.

Carbon Steel

As mentioned before, this type of steel has far lower chromium levels. Instead, it is formed from a carbon-like alloy with a few other materials. The carbon content in this is usually 2-2.5%. Though unlike stainless steel, carbon steel is susceptible to rust, the latter is cheaper and has different mechanical properties depending on its carbon content. Low-carbon steels are generally softer, and hence, can be machined and welded easily. On the other hand, high-carbon steel is stronger, but it is also much harder to process.

Types of Carbon Steel

It is the carbon content that constitutes the defining element of any carbon steel alloy. The various types of carbon steel can be categorized as follows:

Low-carbon steel: This is the most widely used form, with the carbon content being less than 0.25%. Since this is relatively weaker and softer but is more ductile and can be easily welded, this type of carbon steel is used for machining and welding at a low cost.

Medium-carbon steel: This variety usually has a carbon content of 0.25-0.6% and manganese content of 0.6-.1.65%. It can be improved via heat treatment. However, this can be performed only on very thin sections unless alloying elements are added. It is stronger but not as ductile as low-carbon steel.

High-carbon steel: This is the hardest and toughest type of carbon steel. It is the least ductile and is highly resistant to wear and tear. Its carbon content varies from 0.6% to 1.25% while the manganese content is about 0.3-0.9%.