Stainless steel finds wide application in almost every aspect of architecture, building, and construction. Way back in the 1920s, stainless steel made its way into architecture and construction, and over the years, its uses and applications have increased remarkably.

Since stainless steel is visually appealing and functionally utilitarian, it is a boon for the field of architecture. Therefore, it’s no wonder that some of its applications are meant for aesthetic appeal, for example, curtain wall and roofing. On the other hand, some of its uses are more practical and safety-centric, such as masonry and stone anchors, bollards, and safety railings.

The use of stainless steel products in architecture also depends on the alloy concerned. To elaborate, leading architectural firms, landscape design and structural engineering firms use the more highly alloyed alloy of stainless steel, containing molybdenum. Such steel is highly suitable for corrosive locations. It is also essential to consider factors like air pollution, exposure to salt, weather patterns, design and cleaning frequency when selecting a variety of stainless steel for architectural constructions. This will ensure good performance in the long run. More and more structures are being conceptualized by architects and engineers when Architecturally Exposed Stainless Steel (AESS) is the primary design element.

Reasons make stainless steel highly useful in architecture:

a) Strength and Durability

Stainless steel helps in making framing materials exceptionally strong and ductile. As a result, framing members react well to tensile stresses. Stainless steel of high-grade ensures superior structural support, besides allowing a reduction in material thickness. It is more economical as compared to conventional stainless steel grades. If you use it, you won’t have to worry about wear and tear even in the long run.

b) Corrosion-resistance

Stainless steel is, by nature, corrosion-resistant. Its aesthetic appeal further complements its corrosion-resistance. Since it has a natural coating that prevents oxidation, exposure to water, heat, or chemicals does not cause any damage to stainless steel. That’s why stainless steel is best suited for architectural and construction purposes.

c) Design flexibility

Stainless Steel products can be customized into a wide variety of shapes, which are then used for making nearly every component of a structure. If the architect or designer has a unique vision, that can also be easily incorporated, given the versatility of stainless steel. Moreover, it is easy to transport or erect since it is lightweight in nature.

d) Sustainability:

A building construction that uses stainless steel framing components automatically reduces the carbon footprint on the environment. This is because stainless steel is almost 100% recyclable. Whatever waste that is generated in the manufacturing process can be reused to make more steel. What’s more, we can always repurpose demolished stainless steel framing. You can hardly find a more sustainable building material.

Without stainless steel, we’d have had architectural structures that would have fared poorly on aesthetics and functionality, besides having poor resistance to corrosion and high temperatures.

We promise to offer the finest quality stainless steel to meet the needs of any design project. Based out of New Delhi, India, Aamor Inox is a leading manufacturer and supplier of Stainless Steel Rounds, Angles, Squares, Hexagons & Flat Bars. We export our products to over 60 countries worldwide. Please share your enquiries with us on anand@aamorinox.com, and we’ll get back to you soonest.

Often, people mistakenly believe that stainless steel is a single material. In reality, stainless steel refers to a family of corrosion-resistant steels. Therefore, it is very important for a consumer to understand the distinctive properties of various families and grades of stainless steel so that he can make an informed decision.

Even though stainless steel owes its corrosion resistance primarily to chromium, there are many combinations of metals available in the market today, which also fall within the category of ‘stainless steel’.

When you try to find the best option of stainless steel, you must determine the precise kind of alloy you require for your purpose. That will also help you identify the optimal price point according to your need.

The two major stainless steel labels are:

a) Families

b) Grades

Stainless Steel Families

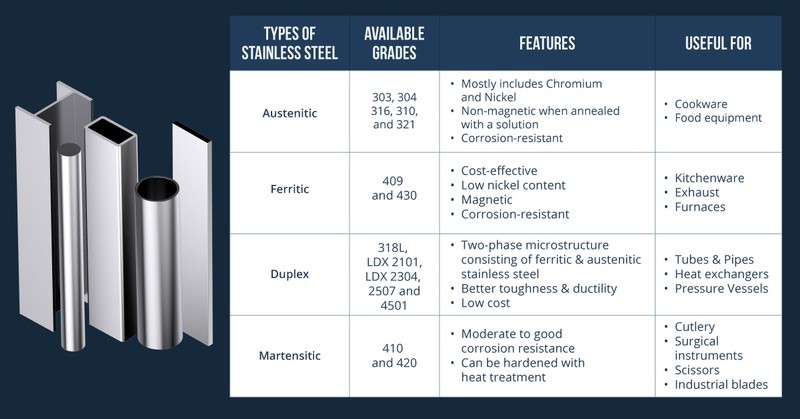

The term ”stainless steel families” in this case refers to specific properties of that particular alloy. Different families have different ratios of various metals in the alloy. The four prominent stainless steel families include:

a) Austenitic

b) Ferritic

c) Duplex

d) Martensitic and Precipitation Hardening Stainless Steel

While families act as a differentiator at one level, you need to really look at grades of stainless steel to appreciate what separates one variety from another. Various grades refer to specific properties of the alloy such as toughness, magnetism, corrosion-resistance, and alloy composition.

Common stainless steel families and grades along with their characteristics:

Pairing a family and grade together gives you a good indication of what to expect from a particular stainless steel alloy. Be it magnetism, toughness, corrosion-resistance or heat-resistance, you can learn about everything by focusing on these two aspects.

The following classifications will make you aware of what to expect within each family as well as common grades.

Austenitic: This is the most widely used family of stainless steel worldwide. It mostly includes chromium and nickel, though some grades also include manganese and molybdenum. Austenitic stainless steel is non-magnetic when annealed with a solution. However, there are also certain cold worked grades that are magnetic. Heat-based hardening does not work for this type of stainless steel. However, it promises excellent corrosion-resistance and is also highly weldable. Austenitic stainless steel’s popular grades include 303, 304, 316, 310, and 321 grades.

Ferritic: This is one of the most cost-effective families of stainless steel available in the market. It has a low nickel content but includes chromium, molybdenum, niobium, and/or titanium. These metals improve the toughness and creep resistance of this alloy. This variety is magnetic, highly corrosion-resistant and weldable. Its most popular indoor applications include kitchenware, exhaust etc. This family is well-suited for applications where cost and performance matter more than visual appeal. Common grades of ferritic stainless steel include 409 and 430 grades.

Duplex: This family includes most of the recent and proprietary stainless steel alloys. If you opt for duplex grades, you can benefit the most from its properties, which are a combination of both austenitic and ferritic stainless steels’ properties. When it comes to the Duplex family of stainless steel, its characteristics depend upon the specific alloy. The characteristics include weight, toughness, and tensile strength. A number of alloys are created based on specific industrial concerns. This family of stainless steel is also available in a chloride-resistant variety, which is popular in offshore use. In this family, the common grades include 318L, LDX 2101, LDX 2304, 2507, and 4501.

Martensitic and Precipitation Hardening: Martensitic and precipitation hardening steels are the most common of the four major families of stainless steel. These are popular in applications that need a precise and hardened edge. This family is also the best choice for making knives, scissors, razors, and medical tools. This stainless steel alloy promises moderate to good corrosion-resistance and retains its magnetism after hardening. 410 and 420 grades are the common grades of martensitic and precipitation hardening steels. Be it making ornamental structures or rugged industrial applications, stainless steels have a wide range of usages and applications. It is crucial to understand the unique characteristics of different stainless steel alloys so that you make the right choice.

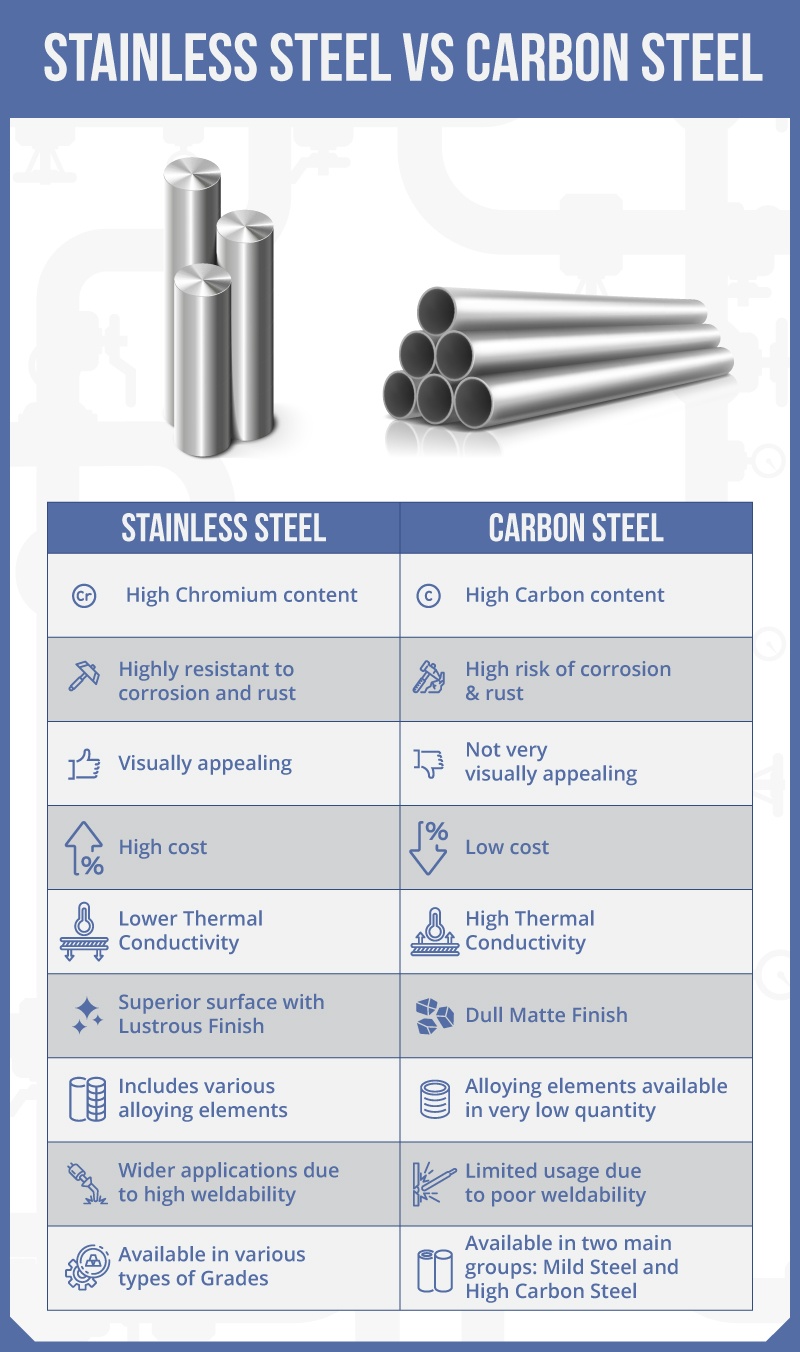

Steel as a broad term is loosely used to refer to an entire family of metal alloys. It is a common, highly versatile metal with a wide range of applications and uses. Steel comes in different grades but generally speaking, it can be divided into two categories: a) Carbon Steel b) Stainless Steel.

The basic attribute that differentiates the two is the chromium content. While carbon steel contains less than 10.5% of chromium, stainless steel must have at least 10.5% of chromium to be classified as the same. It is this characteristic that lends different properties to the two types of steel.

Difference between Stainless Steel and Carbon Steel:

Stainless Steel

This is mainly defined by the addition of chromium, along with certain other alloying elements such as nickel. It is also termed as ínox’ steel, as it is crafted to protect against oxidization, and hence, it is ínoxidizable’. Equipped with the protective layer of chromium which safeguards the metal’s iron content from being oxidized due to exposure to environmental oxygen, stainless steel is corrosion-resistant and thus called ‘stainless’.

Types of Stainless Steel

Depending on the chromium levels, stainless steel can further be divided into various categories. Usually, stainless steel with lower chromium content is cheaper and less durable. The following are the types of stainless steel with different properties:

Austenitic: This is the most widely used type of stainless steel, offering low yield strength but strong corrosion and heat resistance. It is commonly used in housewares, industrial piping and vessels, construction, and architectural facades.

Ferritic: This form of stainless steel usually does not contain nickel. However, this promises better corrosion, heat, and cracking resistance as compared to most other types. This form of stainless steel is frequently used in washing machines, boilers, and indoor architecture.

Martensitic: This is usually magnetic and due to its low chromium content, is not as corrosion-resistant as other types of stainless steels. It’s also very strong, and therefore, it’s used to make knives and turbine blades.

Duplex: This is a composite of austenitic and ferritic steels, and is thus, very strong and flexible. It boasts twice the yield strength of austenitic stainless steel and finds wide usage in industries such as paper, pulp, shipbuilding, and petrochemical industries.

Precipitation: This type of stainless steel has the same level of corrosion resistance as austenitic metals, but can be hardened to make it even stronger by adding other elements such as aluminum, copper, and niobium.

Advantages of Stainless Steel

– Corrosion-resistant

– High and low temperature-resistant

– Comes in different types

– Strong and highly durable

– Low-maintenance and can be easily cleaned

– Long-lasting

– Low-priced as compared to its lifespan

– Can be customized for an attractive cosmetic finish

– Does not tarnish easily

– Environment-friendly and recyclable

Applications:

Stainless Steel has a range of applications in many industries. The first industrial application of stainless steel took place way back in the 1930s by Ford, in the automotive industry. Ever since then, it has made its way into cars for exhaust systems, grills, trims, and different structural components. It is also used in aircraft construction, for making aeroplane frames, jet engines, and landing gear. Its corrosion-resistance and low-maintenance properties makes stainless steel highly useful for transporting and interacting with chemicals. Medical technology uses stainless steel too.

Thanks to its strength, resistance, and flexibility, certain types of stainless steels are used in architecture. The aesthetic features and attractive finish of stainless steel further enhance its desirability in architectural applications. It can also be cleaned easily. No wonder stainless steel’s price is considerably higher than carbon steel.

Besides, stainless steel is commonly used in the food and catering industry to manufacture cookware, cutlery, kitchen accessories, and appliances. It is interesting to note that the less ductile grades of stainless steel are used to make utensils such as knives, while the more ductile grades are used in the manufacture of grills, ovens, saucepans, and sinks.

Carbon Steel

As mentioned before, this type of steel has far lower chromium levels. Instead, it is formed from a carbon-like alloy with a few other materials. The carbon content in this is usually 2-2.5%. Though unlike stainless steel, carbon steel is susceptible to rust, the latter is cheaper and has different mechanical properties depending on its carbon content. Low-carbon steels are generally softer, and hence, can be machined and welded easily. On the other hand, high-carbon steel is stronger, but it is also much harder to process.

Types of Carbon Steel

It is the carbon content that constitutes the defining element of any carbon steel alloy. The various types of carbon steel can be categorized as follows:

Low-carbon steel: This is the most widely used form, with the carbon content being less than 0.25%. Since this is relatively weaker and softer but is more ductile and can be easily welded, this type of carbon steel is used for machining and welding at a low cost.

Medium-carbon steel: This variety usually has a carbon content of 0.25-0.6% and manganese content of 0.6-.1.65%. It can be improved via heat treatment. However, this can be performed only on very thin sections unless alloying elements are added. It is stronger but not as ductile as low-carbon steel.

High-carbon steel: This is the hardest and toughest type of carbon steel. It is the least ductile and is highly resistant to wear and tear. Its carbon content varies from 0.6% to 1.25% while the manganese content is about 0.3-0.9%.

Stainless Steel Pump Shaft Quality Bars are manufactured with absolute precision to ensure that they are able to withstand extreme and exhaustive environments. Also known as Stainless Steel PSQ Bars, these bars are processed from ultra-modern combined lines and highly advanced equipment.

Aamor Inox, a high-end stainless steel round bar manufacturer in India, produces Stainless Steel Pump Shaft Quality Bars as a premium product line. These bars are tested via Ultrasonic Inspection & Eddie Current Testing to ensure these top-quality bars are devoid of any sort of internal defects. The finishing work is done using the specially-designed finishing machines that ensure the surface roughness and the size tolerances (including the out of roundness) are achieved.

Aamor Inox offers PSQ Bars in the size range of 6mm – 100 mm (1/4 – 4 inches) within lengths of up to 8 meters (upto 26 feet). The size tolerances of these PSQ Bars are available in j6, e6, h6, f6, f7, h7, f8, h8, h9, ½ of A484 etc in heat treatments such as Annealed, Solution Annealed, Quenched & Tempered (QT), Hardened & Tempered (HT), Quenched & Double Tempered (QDT). The heat treatment under rigorously high temperatures help in having a higher degree of uniformity in its molecular structure that further helps the metal to maintain its structure under extreme or evolving external conditions.

Aamor Inox also provides PSQ bars with the straightness of 0.25 mm per meter max (0.0015” per feet). This is extremely helpful to minimise the vibrations that the shafts experience during high-speed rotations. The high degree of straightness that Aamor Inox implements during manufacturing is ideal for the bars.

The PSQ bars by Aamor Inox go through an optimal crack test via Eddy Current Testing through Circograph (from Dr Foerster, Germany) and Magnetic Particle Inspection (MPI). This ensures that the bars require minimum maintenance and is effective in the long run.

Aamor Inox is rightly considered as India’s most advanced producer of ‘Specialty Stainless Steel’ long-products and manufactures semi-finished and cold-finished long products in specialty stainless steels. The brand is known for its end-to-end manufacturing and efficiently fulfils the unique requirements and specifications of all its clients. To learn more, contact Aamor Inox today!