Stainless Steel bars are a common raw material used in construction and finishing work. They are widely used across all manner of industries and applications. Some common applications are architectural design, marine equipment, oil/gas pipelines, automotive components, etc.

Stainless steel rods and bars have a number of valuable characteristics, the most prominent being corrosion resistance. These rods are available in different shapes and formats in the market, which includes round bars, flat bars, square bars, and hexagonal bars.

Stainless Steel Bars are either hot rolled or cold drawn. Hot-rolled bars have a comparatively rough surface than the drawn bars. These bars are used only for their strength and corrosion resistance property. On the other hand, cold drawn bars are used in aesthetic applications and outdoor fixtures. Cold drawn bars are preferred due to their smooth surface. One such cold drawn bar is a stainless steel piston bar, which is a variant of stainless steel round bars. The general range of stainless steel piston high-quality bars is from 6mm to 100mm radius.

Key Characteristics of Stainless Steel Piston Bars

- Since stainless steel is a relatively strong material, stainless steel piston rods are the best choice for structural applications.

- Being non-porous is a key factor that makes stainless steel cold drawn bars corrosion-resistant.

- Cold rolled piston bars made of stainless steel have a smooth surface, which makes them hygienic, low in maintenance, and non-reactive to many substances. That’s why they are commonly used in kitchen environments.

At Aamor Inox, we offer premium stainless steel piston rod quality bars that are processed in our ultra-modern facilities to make high-grade steel of international standard. To avoid any internal defects in the finished product, we use Ultrasonic Inspection and Eddy Current Testing. The finishing is done by specially designed machines to ensure that the size tolerance and surface roundness are achieved as desired.

Our cold drawn bars go through various types of heat treatment and are 100% tested through digital ultrasonic flaw detectors to ensure the premium quality. Our cold-rolled stainless steel piston rod quality bars can be used in pump shafts, hydraulic piston shafts, cylinder shafts, boat shafts, bearing sized shafts, and chrome plating quality bars.

| Size Range | 6 mm – 100 mm (1/4 – 4 inch) |

| Size Tolerances | j6, e6, h6, f6, f7, h7, f8, h8, h9, ½ of A484 etc |

| Length | 1 meter upto 8 meters (upto 26 feet) |

| Ovality | Half of diameter tolerance |

| Heat Treatment | Annealed, Solution Annealed, Quenched & Tempered (QT), Hardened & Tempered (HT), Quenched & Double Tempered (QDT) |

| Straightness | 0.25mm per meter max (0.0015” per feet) |

| Surface Finish | Ra – 0.2 um / 12 RMS max |

| Chamfering | Available in 30, 45 & 60 degree thru fully automatic both-end chamfering machine |

| Crack Test | Eddy Current Testing thru Circograph (from Dr. Foerster, Germany) and Magnetic Particle Inspection (MPI) |

| Ultrasonic Test | 100% tested thru Digital Ultrasonic Flaw Detector, as per ASTM A-388, EN 10308 (class 1 to 4), API 6A/ISO 10423:2003-PSL 3, SEP 1920:1984 (class A, B, C), MIL STD 2154 |

| Length Tolerance | Available in special cut to length bars in tolerance – 0/+10mm (-0 +0.5 inch) |

| Grades | 303, 304L, 310S, 316L, 316Ti, 321, 403, 410, 416, 420, 420B, 420C, 430F, 431, 17-4ph, Duplex F51 (2205) 1.4305, 1.4307, 1.485, 1.404, 1.4571, 1.4541, 1.4006, 1.4005, 1.4021, 14028, 1.4034, 1.4104, 1.4057, 1.4542, 1.4462 |

| Packaging | Packing is done using a variety or protective materials & distance rings, and then placed in the strong plywood boxes to ensure safety of material during transportation. |

Based out of Delhi/NCR, India, Aamor Inox is a leading manufacturer and supplier of Stainless Steel Piston Rod Bars. These can be customized into different sizes and grades with excellent accuracy according to the requirements of the client at reasonable prices. We export our products to over 60 countries worldwide. Please share your inquiries with us on anand@aamorinox.com and we’ll get back to you as soon as possible. If you’re interested in the purchase of any stainless steel metal product, here is our contact number 0120-4564585. You can also request a quotation online by filling the form below.

Stainless steel round bars are corrosion-resistant and rust-free, which makes them suitable for use in huge factories dealing with chemicals. Besides being resistant to heat and fire, stainless steel does not corrode, as it does not react to chemicals.

Made of a durable alloy with high life expectancy, stainless steel round bars are also stain-free, which lends them an attractive appearance. Additionally, they are heavy and can withstand extreme conditions. These round bars have wide industrial applications, including those that involve chemical processing and/or high-saline environments.

Stainless steel round bars are used in a variety of machinery, mechanisms, valves, fittings, vessels, flanges, threading bars, subways, chemical and fuel tankers, signboards, escalators, elevators, lifts, and petrochemicals.

Stainless steel round bars are also highly useful in the manufacturing of medical surgical instruments, thanks to their non-reactive properties. Durable, easy to clean, perfectly welded and finished, stainless steel bright round bars have some typical applications which include the following:

- Food Preparation Equipment.

- Laboratory Benches and Equipment.

- Boat Fittings.

- Chemical containers, including for transport.

- Heat exchangers.

- Threaded fasteners.

Additionally, stainless steel round bars are used in hydraulics where they get a more cogent internal structure. Their ability to withstand warping and wearing is also considerably high, when used for this purpose.

These mirror-finished round bars are completely machine-made, without involving any human intervention. Therefore, they are not only visually pleasing but also offer absolute precision, ductility, and durability.

Polished Stainless Steel Round Bar Grades

| Grade | Thickness/Diameter |

| SS 304 Round Bar | Upto 5 inches |

| SS 304L Round Bar | 3-4 inch,2-3 inch |

| SS 316 Round Bar | 36 meter,6 meter |

| SS 316L Round Bar | 0-1 inch,3-4 inch |

| SS 303 Round Bar | 3-4 inch |

Sizes of Stainless Steel Round Bars

| Type | SIZES (mm) |

| Cold Drawn and Polish | 3.00 – 75.00 |

| Cold Drawn and Ground | 10.00 – 75.00 |

| Peeled and Polished | 40.00 – 150.00 |

| Peeled and Ground | 20.00 – 50.00 |

Based out of Delhi-NCR, India, Aamor Inox is a leading manufacturer and supplier of Stainless Steel Round Bars. We export our products to over 60 countries worldwide. Please share your enquiries with us at anand@aamorinox.com and we’ll get back to you soonest.

A wire rod is a hot rolled wire, which can have a diameter of anywhere from 5.5 to 42mm. A standard quality rod can be made of various materials such as carbon steel, stainless steel, aluminium, and ordinary quality copper. However, stainless steel wire rods offer unparalleled quality with high corrosion resistance and high weldability. Depending upon the technical parameters of the material type, the cross-section of wire rods can be hexagonal, round or square. But the majority production of wire rods is in round cross-section in nominal diameters of 5mm to 19mm.

Manufacturing of Wire Rods

Wire rods are manufactured by hot rolling billets on continuous rolling mills. It is extracted from hot metal through shafts. The shafts shape and compress the metal from various sides, transforming a piece of metal into a thin, long cable.

The rod needs to be cooled after rolling. This wire is wound on a special winder at the end of the rolling mill for the further cooling process. There are two ways this process can go: by air or rapid cooling. Unlike rapid air cooling, which involves special fans, air cooling happens naturally. The rod is ready for storage after cooling.

Usage of Wire Rods

There are a variety of applications for stainless steel wire rods, such as aviation, industrial, engineering, and for reinforcing concrete structures. These HRAP wire rods can be used in cold drawing, metal wiring, binding, fastener applications and to make stainless steel wire mesh.

Stainless steel wire rods are mainly used to produce stainless steel wire. In order to manufacture downstream products such as industrial fasteners, springs, medical and dental devices, automobile components, and welding electrodes, stainless steel wire is used.

In India, Aamor Inox is one of the leading manufacturers and suppliers of premium quality Stainless Steel Wire Rods. We provide exceptional quality stainless steel rods in various AISI and DIN International standard grades and sizes. Our division is well equipped with the necessary machinery and tools where the process of solution annealing is done in a controlled environment. We have expertise in in-house melting operations to produce the best quality annealed stainless steel wire rods.

Based out of New Delhi, India, Aamor Inox exports various stainless steel products to over 60 countries worldwide. Please share your enquiries with us on anand@aamorinox.com, and we’ll get back to you as soon as possible.

Stainless steel angles are the simplest but one of the most easily identifiable profiles of stainless steel. It comes with several benefits for a variety of uses. Stainless steel angles are one of the most common structural shapes in building and construction. In its simplest form, you can expect a stainless steel angle with the shape of an L and flat surfaces that extend both horizontally and vertically. These surfaces meet at a 90 degrees angle. Available in both equal and unequal leg dimensions, these stainless steel angles are manipulated by engineers. They basically play around with the strength distribution of each leg, depending on the design required.

Since stainless steel angles are light and compact, they are very easy to work with, irrespective of the application. They are also very versatile, as they come in different sizes and alloys. Using stainless steel angles in your design will minimize replacement costs and enhance the life-cycle of the structure concerned. The most common production methods of stainless steel angles include –

- Laser fusion

- Hot rolling

- Cold drawn

Stainless steel angles uses

Stainless steel angle finds wide usage in construction, bridges, equipment, framing, shelving, furniture, and so on. They are highly advantageous in corrosion-prone environments such as chemical plants, food and beverage processing plants, marine applications, etc. Since they are made of stainless steel, they are extremely durable and will not get rusted even after years of use. While wooden construction comes with a limited lifespan, stainless steel angles need no replacement for a long period of time. Equipped with weather protecting feature, stainless steel angles when used to make roofs, can shed winter snow easily and also keep the home cool during the hot and sultry summers. These stainless steel angles are also highly resistant to fire, insects, rot, and mildew.

Whether you own a construction firm or are simply a homeowner, you can reap the benefits of a well-constructed property by using stainless steel angles. With distinct shapes, these are not only reliable but promise high value-for-money. Wood or lumber often fails to provide that specific structure with sufficient support that you need, which on the other hand, is guaranteed by stainless steel angles. They come in various sizes and lengths to fit your needs.

Aamor Inox is one of the leading manufacturers and suppliers of stainless steel angles with the length being around 6 metres (20 feet). We offer size ranges of 20x20x3mm up to 80x080x8mm. we will cater to your customized requirements and ensure absolute satisfaction with our product quality and specifications.

Stainless steel is an alloy made up of different metals. When these metals are mixed in different quantities, they produce several variations of the alloy. Each variation has its own features and uses. There are over 150 varieties of stainless steel, and each of them has different properties, which are further split into grades.

For the food service industry, there are two types of stainless steel: SAE Grades and Flatware Grades. These two grades are commonly known as food-grade stainless steel.

Stainless steel is a fantastic metal, and that’s why it’s so widely used in the kitchen. It doesn’t break, bend or crack and stays shiny for years. Ever wondered why it’s so commonly used in the food service industry? Why not aluminium? Why not iron? Let’s find out.

Benefits of using stainless steel utensils:

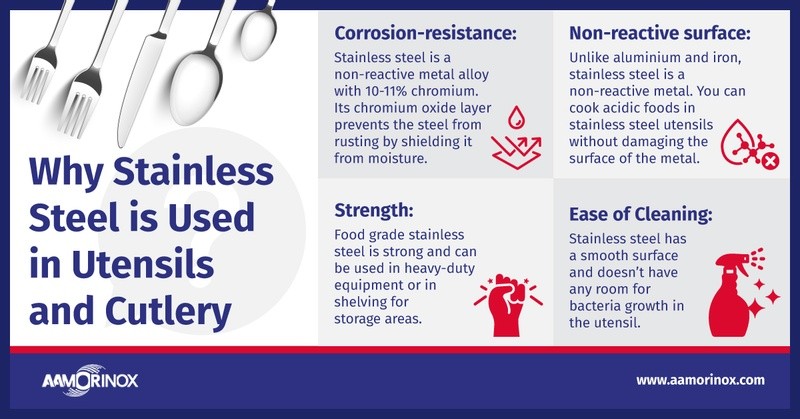

- Corrosion-resistance: Stainless steel is a non-reactive metal alloy with 10-11% chromium. On being exposed to air, chromium forms a layer of chromium oxide over the surface. This layer prevents the steel from rusting by shielding it from moisture.

- Non-reactive surface: Unlike aluminium and iron, stainless steel is a non-reactive metal. It means you can cook acidic foods in stainless steel utensils without affecting the flavour of the food and without damaging the surface of the metal.

- Strength: Food grade stainless steel is strong and can be used in heavy-duty equipment or in shelving for storage areas.

- Ease of Cleaning: Cleanliness is an essential requirement of the food industry. Usually, wooden or plastic utensils have several openings where bacteria can grow if they are not cleaned properly. Compared to that, stainless steel has a smooth surface, and it doesn’t have any room for bacteria growth in the utensil.

Amongst lots of metals available in the market, stainless steel is considered as one of the best materials for kitchen utensils. It is incredibly useful due to its strength, durability, and corrosion resistance. It’s not just the food industry; stainless steel is useful in countless applications in different other industries as well.

In India, Aamor Inox is one of the leading manufacturers and suppliers of premium quality Stainless Steel products. We cater to diverse clientele around the world by manufacturing high-quality stainless steel products.

We serve different industries like dairy, instruments, pulp and paper, medical, etc. Based out of New Delhi, India, we export various stainless steel products to over 60 countries worldwide. Please share your enquiries with us on anand@aamorinox.com, and we’ll get back to you as soon as possible.